The Oregon Wood Innovation Center continues emphasizes connections to assist Oregon wood products firms solve challenges and pursue new business opportunities. We work to connect industry personnel with our resources and technical information, help connect buyers and sellers of Oregon forest products, and enable industry professionals to network with one another.

Below are highlights of our activities and accomplishments in 2016 and brief details on where we are headed in 2017.

2016 Activities

Publications - A couple new publications were developed this year including:

- Executive Innovation Briefs - Developing an Innovation Strategy; and the MIT Sloan Management Review interviewed us after seeing our innovation brief on the Internet of Things

- Research Briefs - Does Gender Diversity Matter in Forest Sector Companies Matter?

|

- Biomass - our staff developed a new tool for exploring biomass utilization - the Biomass Enterprise Economic Model

- Oregon Industry Tour - we partnered with Lynea Advisory in Melbourne, Australia to develop a tour of Oregon's forests and forest products industry

- Sabbatical Research - OWIC director Scott Leavengood spent June through August in Rotorua, New Zealand working with Scion to conduct research related to wood quailty of radiata pine, a key species used by many Oregon millwork producers

- Contract projects - numerous projects were conducted to help Oregon firms solve problems and explore new products and new markets including:

- Evaluation of wood quality of Willamette Valley ponderosa pine (and also performing test trials on collection of gum/resin from the species)

- Assistance with new product development:

- Determination of the manufacturing parameters and material properties of composite panels made from agricultural residues

- Evaluation of bending properties and screw withdrawal strength of new constructions of hardwood plywood for 3 companies

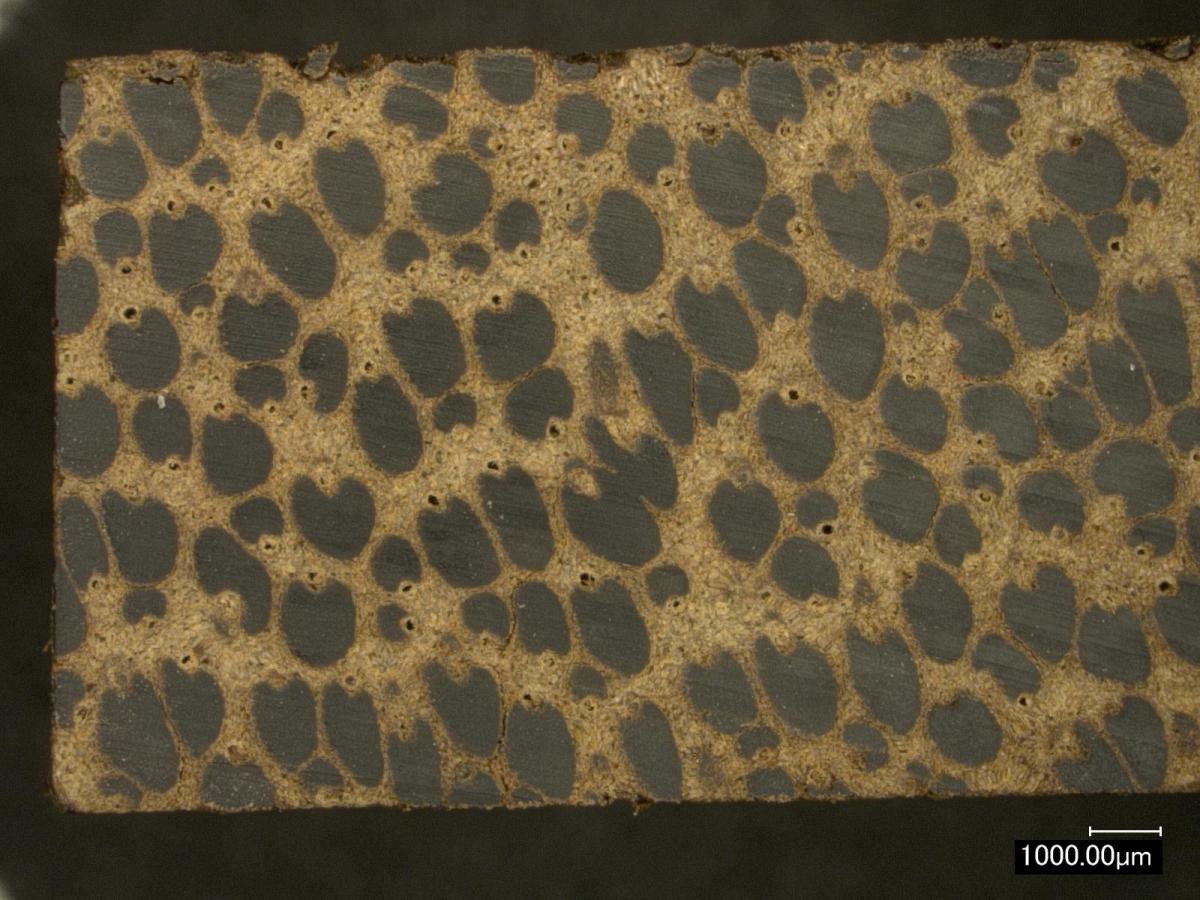

- Measurement of the mechanical and physical properties of sugar palm

- Development of a time-lapse video to document the efficacy of anti-microbial coatings on wood composites

- Several projects related to hardwood plywood and flooring manufacturing and performance:

- Determination of the cause of warp in laminated panels

- Validation of methods to eliminate discoloration in-service for eucalyptus plywood

- Continuation of our research into veneer checking in hardwood plywood and engineered flooring

- Measurement of hardness of Chinaberry flooring and reclaimed southern pine flooring

- Measurement of performance of reclaimed flooring and ability to continue to reclaim and reuse the material depending on installation method

- Other projects during the year included several requests for wood identification, and testing of adhesive bonds in exterior exposure for doors

Microscope Image of Sugar Palm

Outcomes and Impacts

- One company for whom we conducted testing of internal bond strength of composite materials reported - "This information helped us make an educated decision on the source of raw materials and ultimately will save us some serious $."

- We continue to work quite closely with Formology, in Hubbard, OR in their product development efforts, and it is exciting to see the wide array of new products the company continues to launch.

Work In Progress

We also continue to focus on both short-term problem-solving technical assistance as well as longer-term efforts to assist Oregon firms remain competitive in the global marketplace. Examples of work-in-progress include:

- Research and Technical Assistance - several projects are currently underway including:

- Continuing work on the properties of sugar palm - shrinkage, density, hardness, impact resistance, bending properties, durability, and adhesive bond strength

- We've been assisting the Softwood Export Council with a project to develop trade show displays of various grades of western softwoods.

- One of our Renewable Materials students will be working as an intern for Accsys Technologies in The Netherlands to help test the properties of Accoya wood - acetylated radiata pine and red alder.

- Tall Wood Institute - Check out the progress at http://tallwoodinstitute.org/