The Oregon Wood Innovation Center just passed its 10 year anniversary and continues to emphasize connections to assist Oregon wood products firms solve challenges and pursue new business opportunities. We work to connect industry personnel with our resources and technical information, help connect buyers and sellers of Oregon forest products, and enable industry professionals to network with one another.

Below are highlights of our activities and accomplishments in 2015 and brief details on where we are headed in 2016.

2015 Activities

Publications

- Resources for innovators:

- there are now nine publications available in the Wood-based Entrepreneurs Toolkit: Starting a Business, Strategic Marketing, Communicating Effectively with Your Customers, Public Relations, New Product Development, Finding Market Information, Operational Planning, Quality Management, and Pricing Your Products & Services.

- One new Executive Innovation Brief was developed this year: The Internet of Things: Opportunity for the Forest Sector?; and MIT's Sloan Management Review followed-up on this topic with an article on The Internet of Trees.

- Performance Excellence in the Forest Products Industry - we concluded this long-running series with an additional 3 publications on quality control - Variables Control Charts, Attributes Control Charts, and Process Capability Analysis.

|

- Contract projects - numerous projects were conducted to help Oregon firms solve problems and explore new products and new markets:

- Assistance with new product development:

- Determination of the manufacturing parameters and material properties of composite panels made from agricultural residues

- Evaluation of wood quality for hybrid poplar based on clone and position within the stem

- Evaluation of bending properties and screw withdrawal strength of new constructions of hardwood plywood for 3 companies

- Assessment of hardness of acetylated radiata pine and red alder

- Several projects related to hardwood plywood and flooring manufacturing and performance:

- Assessment of veneer checking in maple plywood for 3 companies

- Measurement of swelling in Baltic birch plywood

- Testing methods to eliminate veneer discoloration on fire retardant treated panels

- Measurement of hardness for polymer-impregnated flooring

- Hardness comparision of Douglas-fir and hemlock flooring

- Other projects during the year included several requests for wood identification, exploration of veneer 'springback' following pressing, and determination of the cause of a striped pattern developing in hardwood plywood

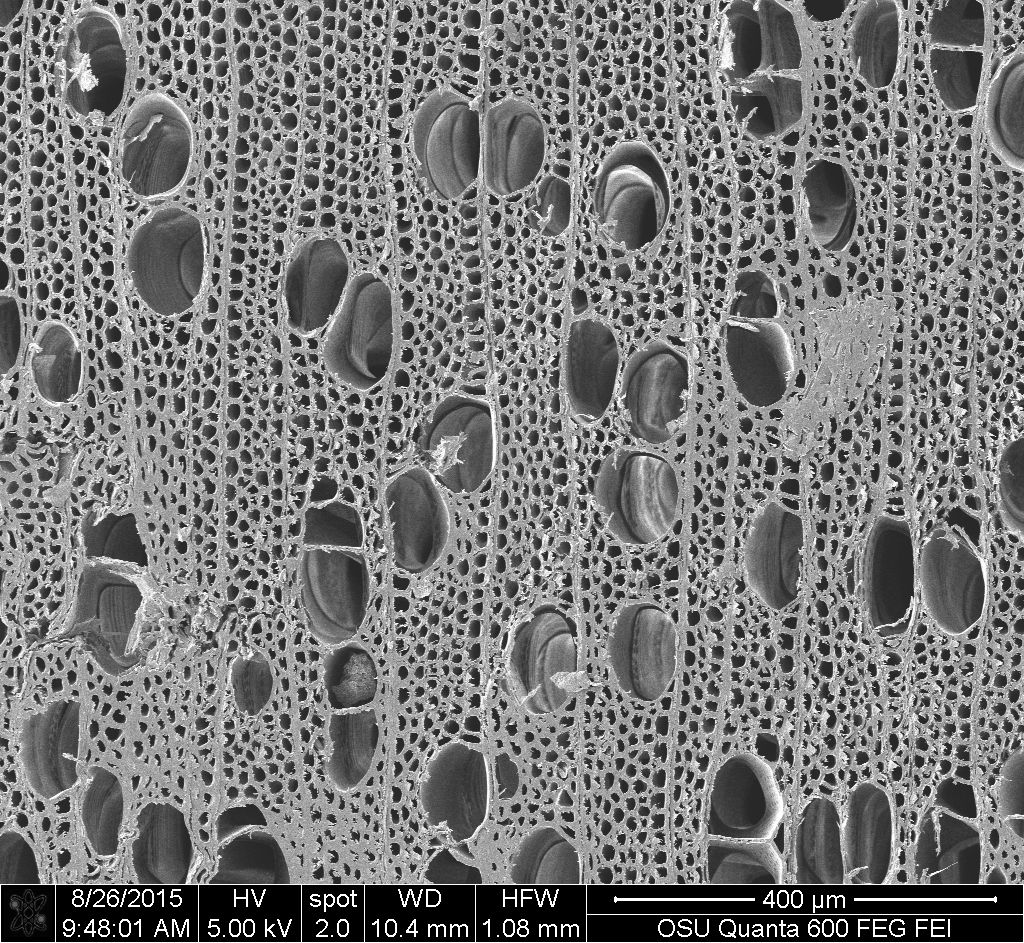

Scanning Electron Microscope Image of Hybrid Poplar - Assistance with new product development:

Outcomes and Impacts

- A participant in the Forest Products Management Development course stated: "This workshop is a valuable experience for developing leaders in our organization. It has continued to grow, evolve, and improve since my first participation in the workshop back in 2007. The true value of the workshop is as much in the interaction and networking that develops between peers in the industry as it is in the content of the training. The projects developed by our teams in the last 2 years have been put into action at the plant and are earning us real return to the bottom line. These projects have added an additional $120,000 per year through a combination of operational cost savings, improved reliability, and gains in quality. The individuals who receive this training are now able to identify opportunity, quantify the potential gains, and apply financial analysis to move projects forward. I intend to keep sending our developing plant leadership to this workshop in years to come. As well it’s a great opportunity for myself to be a mentor for these individuals and coach them through the process."

Work In Progress

We also continue to focus on both short-term problem-solving technical assistance as well as longer-term efforts to assist Oregon firms remain competitive in the global marketplace. Examples of work-in-progress include:

- Research and Technical Assistance - several projects are currently underway including:

- Continuation of our research into veneer checking in hardwood plywood and engineered flooring

- Evaluation of wood quality of Willamette Valley ponderosa pine (and also performing test trials on collection of gum/resin from the species)

- Measurement of performance of reclaimed flooring and ability to continue to reclaim and reuse the material depending on installation method

- Development of a time-lapse video to document the efficacy of anti-microbial coatings on wood composites

- Biomass -Our faculty are playing a key role in the research and outreach teams related to the multi-year Northwest Advanced Renewables Alliance (NARA) project

- Workshops & Webinars - new modules for the wood composite science distance education short course continue to be developed as is our fourth annual OWIC Innovation Days

- Oregon Industry Tour - we are working with Lynea Advisory in Melbourne, Australia to develop a tour of the Oregon forest and forest products industry

- Sabbatical Research - OWIC director Scott Leavengood is planning to spend June through August in Rotorua, New Zealand working with Scion to conduct research related to wood quailty of radiata pine