The Oregon Wood Innovation Center continues to emphasize connections to assist Oregon wood products firms solve challenges and pursue new business opportunities. We work to connect industry personnel with our resources and technical information, help connect buyers and sellers of Oregon forest products, and enable industry professionals to network with one another.

Perhaps the biggest step we made in 2014 was a complete overhaul of the Oregon Forest Industry Directory. The programming behind the directory was nearly 10 years old and so it was long overdue for an update. And we've responded to your requests! The directory now provides the map location of all the listings. Have a look at www.orforestdirectory.com

Below are highlights of our other activities and accomplishments in 2014 and brief details on where we are headed in 2015.

2014 Activities

Publications

- Resources for innovators:

- the first six publications in the Wood-based Entrepreneurs Toolkit series are now available: Starting a Business, Strategic Marketing, Communicating Effectively with Your Customers, Public Relations, New Product Development and Finding Market Information. In addition, 2 new publications were developed in 2014 that are still in the publishing shop: Operational Planning and Quality Management. We expect these newest 2 publications will be ready for download by Spring, 2015.

- Three new Executive Innovation Briefs were developed this year including: Are you an Innovation Leader?, Enhancing Innovativeness Through Attracting More Women into Your Workforce, and Business Model Innovation in a Circular Economy.

|

|

- Contract projects - numerous projects were conducted to help Oregon firms solve problems and explore new products and new markets:

- Several new time-lapse videos in our collection on wood movement (e.g., shrink/swell, warp, adsorption, etc.).

- Assistance with new product development:

- Determination of the strength of fasteners in wood ceiling panels

- Comparison of stem wood vs. root wood strength for furniture parts

- Several projects related to hardwood plywood and engineered flooring manufacturing:

- evaluation of strength, stability and hardness of flooring for TerraMai

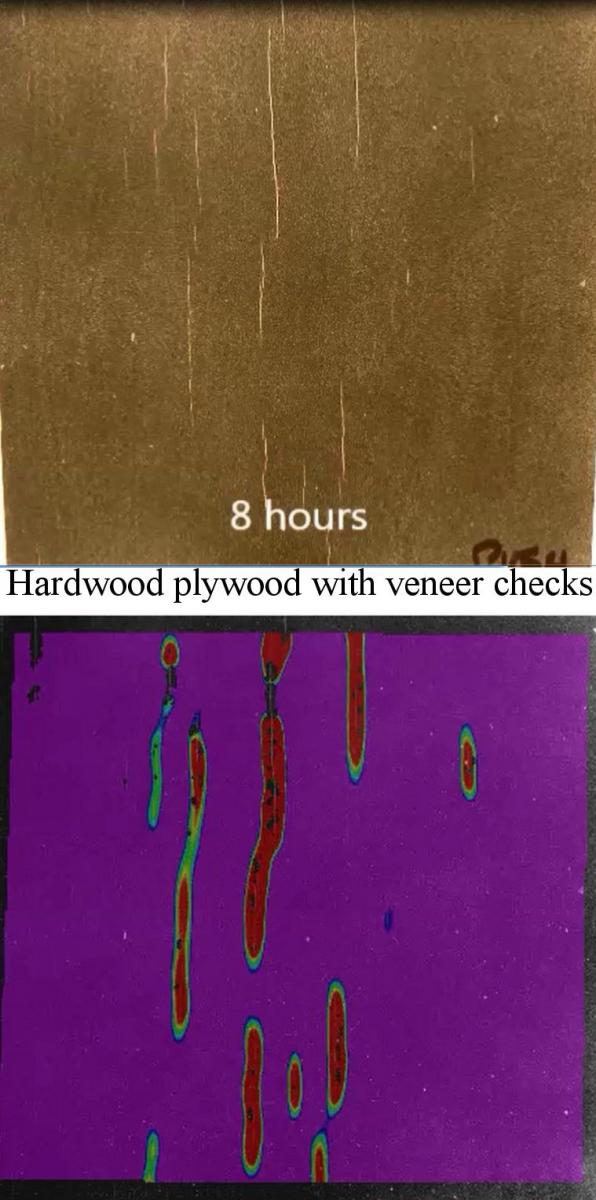

- assessment of veneer checking in maple plywood

- validation of methods to eliminate veneer discoloration in plywood

- measurement of bending stiffness and screw withdrawal strength of 2 new plywood constructions

- assessment of cause of resin bleed-through on alder panels

- determination of the cause of discoloration on maple engineered flooring (blame it on Fido....)

- Other projects during the year included several requests for wood identification (including for parts of a 1912 car), testing bending stiffness of guitar necks, assessment of poplar wood quality for Greenwood Resources, and testing the durability of adhesives for exterior doors

Checks identified and measured using Digital Image Correlation

Outcomes and Impacts

- We have been assisting Greenwood Resources with assessments of the wood quality of Pacific Albus (hybrid poplar) for several years now. While this work is still in the early stages, Austin Himes, Research Plot Coordinator with Greenwood Resources said, “your lab has provided the data to characterize lumber quality variation between varieties which will improve customers' satisfaction and may lead to new product lines. The precision testing is also shedding new light on within stem variation in wood properties which will inform future sampling procedures and log merchandising.”

- Mike Simington, North American Sales Manager with Garnica Plywood, reported that the “Oregon Wood Innovation Center performed fit for purpose testing on our European poplar core hardwood plywood products. The information they provided gave us the confidence to introduce our product line more aggressively in North America leading to over $10 million in incremental sales in 2014.”

- Terra Mai, reclaimed flooring manufacturer in White City, OR stated: "The Wood Innovation Center helped us test our engineered wood flooring for strength, hardness and stability. Without this data, our sales representatives were unable to provide any meaningful assurances to potential customers as to the physical properties of the flooring. With the testing, our representatives have much more factual data and our sales people have much more confidence in the product. Our market introduction in 2014 was highly successful, with one item in particular being the most successful new product the company has ever introduced."

Work In Progress

We also continue to focus on both short-term problem-solving technical assistance as well as longer-term efforts to assist Oregon firms remain competitive in the global marketplace. Examples of 'work in progress' include:

- Research and Technical Assistance - several projects are currently underway including:

- Exploration of the correlation between wood material properties and acoustics for musical instruments

- Continuation of our research into veneer checking in hardwood plywood and engineered flooring

- Evaluation of hardness for acetylated radiata pine and red alder

- Developing more time-lapse videos related to veneer checking

- Assisting 2 entrepreneurs develop new renewable materials-based composite panel products (innovative ideas here! Stay tuned)

- Biomass -Our faculty are playing a key role in the research and outreach teams related to the multi-year Northwest Advanced Renewables Alliance (NARA) project

- Workshops & Webinars - new modules for the wood composite science distance education short course continue to be developed as is our third annual OWIC Innovation Days, and a new course in collaboration with the Forest Products Society - an Introduction to Wood Science & Forest Products