Ponderosa pine is one of the most widely-distributed pine species in western North America; it extends from western Canada to central Mexico. There is a unique population of the species in western Oregon known as Willamette Valley ponderosa pine or simply as 'Valley pine.' As is generally the case, wood properties vary with growing conditions - and little is currently known about the wood properties of Valley pine.

In the winter of 2017, we began 'the Valley Pine wood quality project'; we have determined several commonly-reported wood properties including:

- Specific Gravity (similar to density) - green, 12% moisture content, and ovendry (i.e., 0% moisture content)

- Hardness (often called Janka hardness) - green and at 12% moisture content

- Shrinkage - green to ovendry

- Bending strength and stiffness (MOR and MOE) - green and at 12% moisture content

- Machinability - quality of shaped specimens with a CNC router

- Treatability - ability to accept commonly used wood preservatives

Green property testing began in mid March and was completed on May 11th. Kiln drying (to get to 12% moisture content for dry property testing) of remaining boards began 4/27/2017 and finished 5/5/2017.

Dry property testing was completed 7/10/2017.

Machinability testing was completed 6/10/2018.

Treatability testing was completed in August of 2018.

A fifth log was added from private landowner property west of Salem, OR in November of 2018 and testing (with the exception of machinability and permeability) was completed in early January of 2019.

(Last update 6/3/2019)

| Tree No. | Age | Top/Butt Diameter (in.) | Elevation (ft.) | Crown Class | Comments |

|---|---|---|---|---|---|

| 1 | 89 | 19.5/21.75 | 980 | Dominant | marginal Douglas-fir site |

| 2 | 39 | 9.25/14.5 | 570 | Intermediate | |

| 3 | 29 | 11/21 | 590 | Super Dom. | very rough, knotty |

| 4 | ~100 | 18/19.5 | 700 | Dominant | some sapstain |

| 5 | ~100 | ?/30 | 650 | ? | ? |

| Tree No. - Log Segment | MOR (psi) Bending Strength (green/12%) [sample size] | MOE (x106 psi) Bending Stiffness (green/12%) [sample size] | Hardness (lbs.)(green/12%) [sample size] | Specific gravity (green/12%/ ovendry) [sample size] | Shrinkage (%) - green to ovendry Tangential/Radial [sample size] |

|---|---|---|---|---|---|

| 1- second log | 5092/8120 [18,15] | 0.85/1.09 [18,15] | 411/474 [11] | 0.38/0.40/0.45 [13] | 5.56/3.83 [10] |

| 1 - butt log | 6219/9499 [15,15] | 0.97/1.31 [15,15] | 483/564 [11,12] | 0.44/0.46/0.49 [9] | 5.15/4.06 [11] |

| 2 - fourth log | 5310/7051 [17,14] | 0.92/0.97 [17,14] | 312/418 [11] | 0.34/0.36/0.38 [22,21,22] | 5.26/3.45 [10] |

| 2 - third log | 5146/7310 [17,17] | 0.84/0.99 [16,17] | 378/442 [11,10] | 0.33/0.36/0.38 [15] | 5.49/3.43 [10] |

| 2 - second log | 5719/9546 [17,14] | 1.04/1.39 [17,14] | 487/531 [12,11] | 0.43/0.44/0.49 [22,18,22] | 5.76/4.20 [13] |

| 2 - butt log | 5914/8480 [17,16] | 1.01/1.12 [17,16] | 559/642 [10,8] | 0.45/0.48/0.52 [16,15,16] | 6.33/4.92 [10] |

| 3 - third log | 3511/5923 [17,15] | 0.42/0.74 [17,15] | 258/311 [11,10] | 0.29/0.32/0.34 [23,22,23] | 5.19/2.88 [10] |

| 3 - second log | 4555/8412 [16,16] | 0.72/1.11 [15,16] | 286/417 [10,14] | 0.43/0.46/0.51 [8] | 6.14/3.04 [10] |

| 3 - butt log | 3401/5315 [14,17] | 0.33/0.52 [15,17] | 307/452 [11,10] | 0.36/0.39/0.41 [18] | 5.81/3.29 [10] |

| 4 - second log | 6313/9320 [15,16] | 1.08/1.23 [15,16] | 415/539 [10,9] | 0.48/0.53/0.57 [13,12,13] | 5.67/4.96 [10] |

| 4 - butt log | 5631/8065 [16,13] | 1.07/1.22 [15,13] | 452/489 [10,11] | 0.44/0.45/0.48 [8] | 5.44/3.84 [10] |

| 5- butt log | 5519/7948 [32,32] | 0.72/0.91 [32,31] | 466/582 [6] | 0.43/0.46/0.48 [25] | 4.84/2.90 [6] |

| Overall Average | 5194/7916 [211,200] | 0.83/1.05 [209,199] | 401/488 [124,123] | 0.40/0.43/0.46 [194,184,192] | 5.55/3.73 [120] |

| Ponderosa pine (from USDA Wood Handbook) | 5100/9400 | 1.0/1.29 | 320/460 | 0.38/0.40/? | 6.2/3.9 |

Machinability Results

Fifty-four specimens were machined on a CNC router following a modified version of ASTM D1666 - Conducting Machining Tests of Wood and Wood-Base Panel Materials. Materials were conditioned to 20C and 65% relative humidity and machined at a spindle speed of 2400 rpm and a feed rate of 346 inches/minute. Following machining, all materials were examined for surface quality. The standard specifies grading for raised grain, fuzzy grain, chipped grain, and rough-end grain. However, the only significant machining issues were fuzzy grain and rough-end grain. The table below is a tally of the number of pieces assigned to each category. A sample image of each of the 4 'grades' is shown in the images below.

Subjective assessment results like these are difficult to interpret. Some general observations are that Willamette Valley ponderosa pine may have some issues with fuzzy grain when machining. The wood from the different trees and log segments performed similarly with respect to machining, however, there may be some correlation between tree age and machining quality in that results were best for the oldest tree and worst for the youngest tree.

| Tree No. - Log Segment | 1 - Minor rough end grain | 2 - Significant rough end grain | 3 - Fuzzy grain (full length of piece) | 4 - Chipped grain | Average Score (for tree) |

|---|---|---|---|---|---|

| 1- second log | 4 | 2 | 2.25 | ||

| 1 - butt log | 2 | 1 | 3 | ||

| 2 - fourth log | 1 | 1 | 1 | 1 | 2.13 |

| 2 - third log | 1 | 4 | 1 | ||

| 2 - second log | |||||

| 2 - butt log | 4 | 2 | |||

| 3 - third log | 3 | 2 | 2.38 | ||

| 3 - second log | 2 | 3 | |||

| 3 - butt log | 1 | 3 | 2 | ||

| 4 - second log | 1 | 3 | 1 | 1.8 | |

| 4 - butt log | 2 | 3 |

1) minor fuzzing on end grain;

2) fuzzing on end grain;

3) fuzzing full length;

4) chip out

Treatability Results

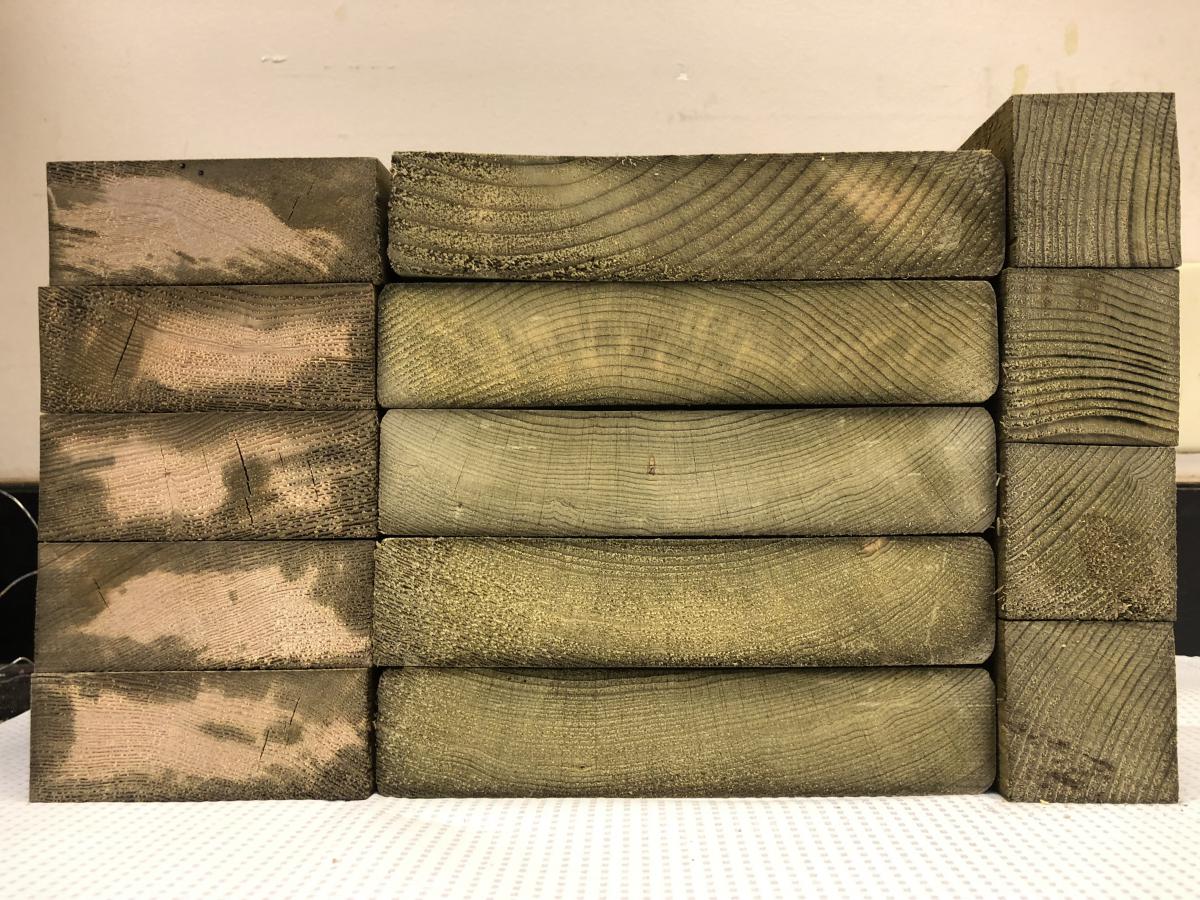

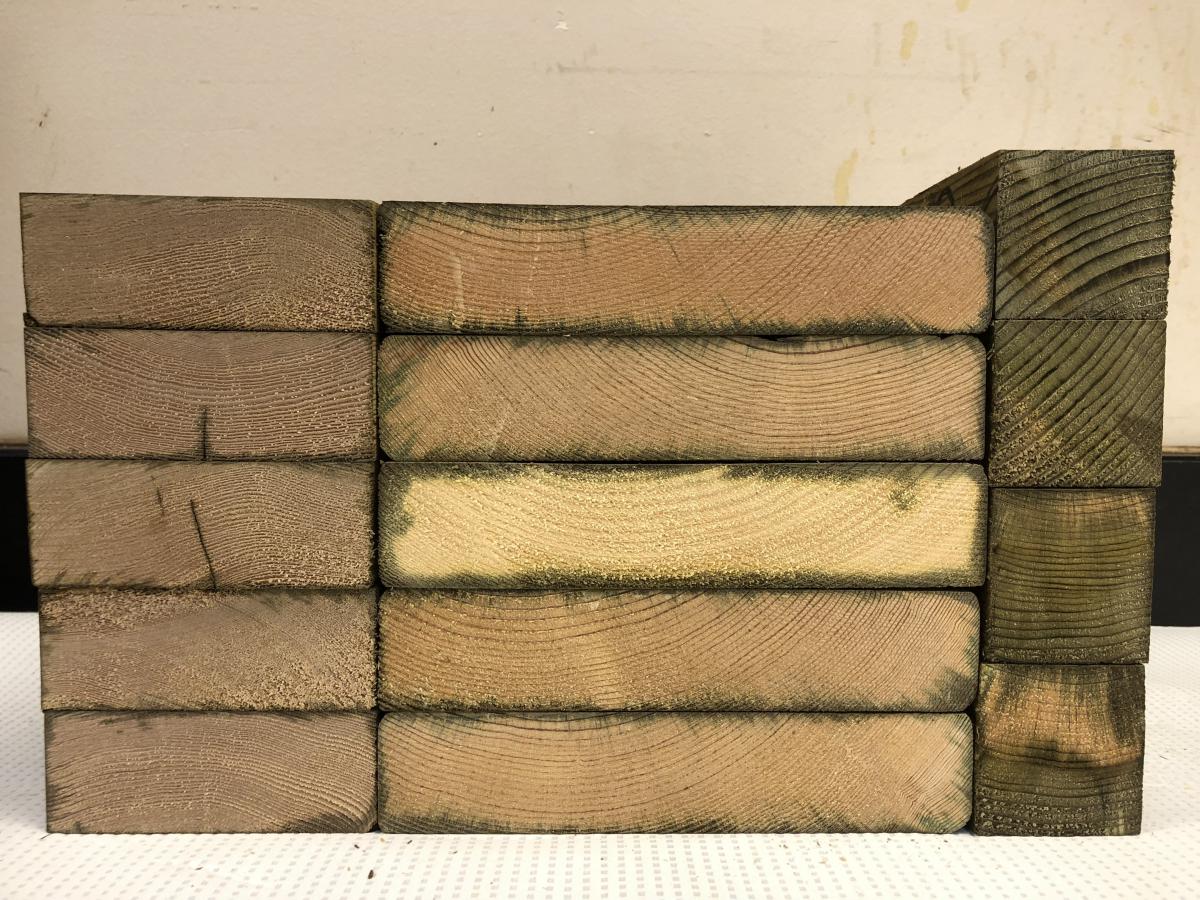

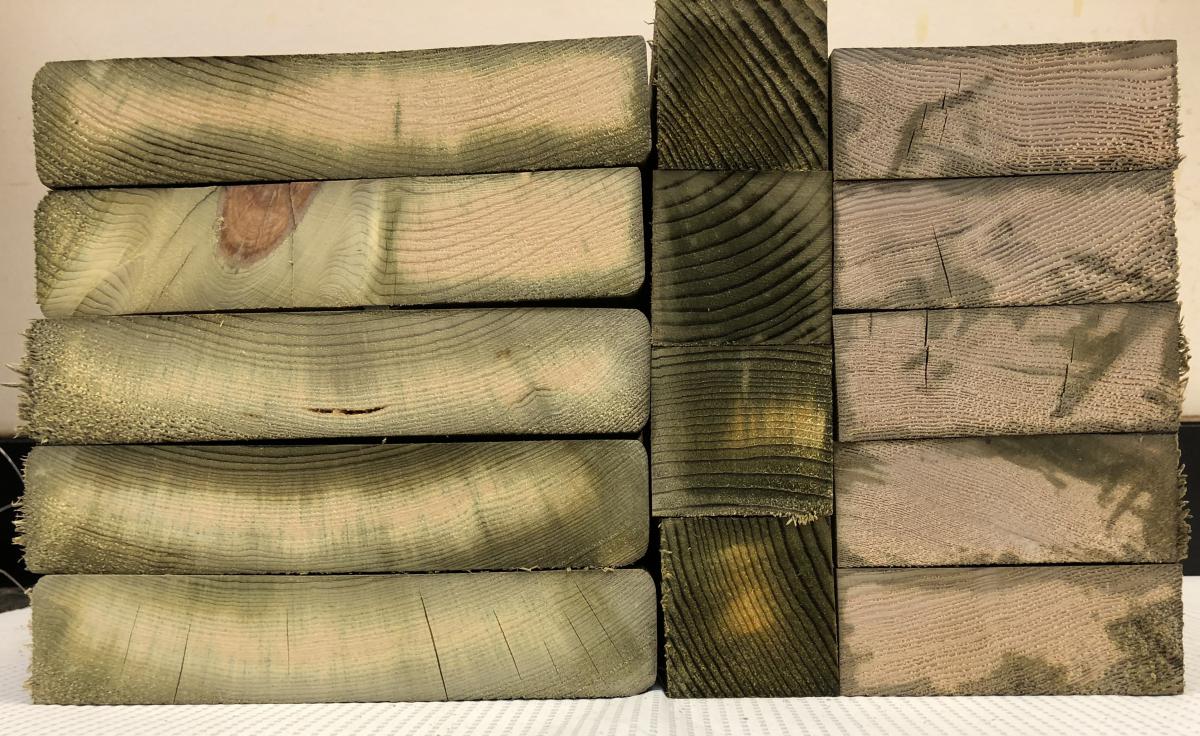

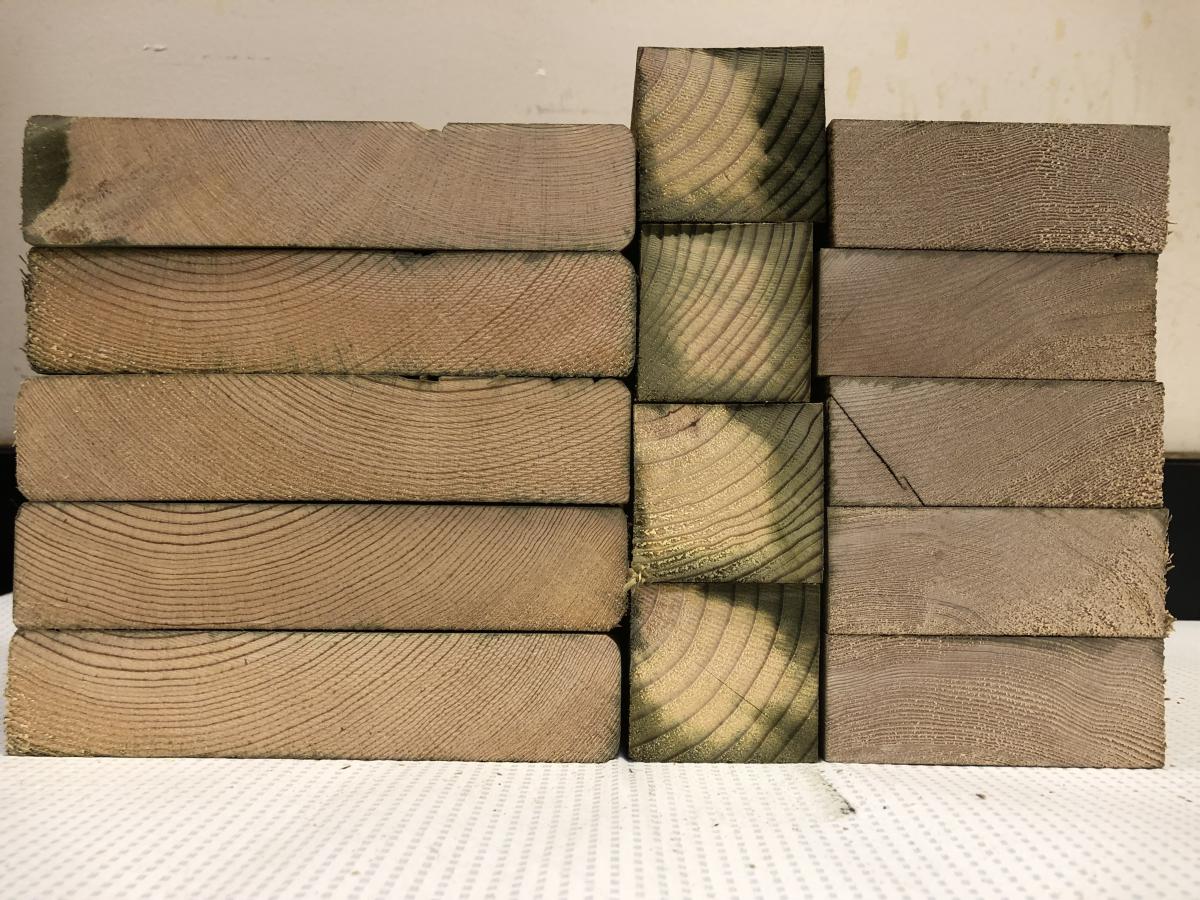

Eighty-two 1.5"x1.5" by 20" long specimens were pressure treated with 2 common water-based wood preservatives: 41 pieces were treated with alkaline copper quaternary (ACQ) and 41 pieces were treated with copper azole type C (CA-C). Specimens were simply placed in alphabetical order (log segments A-K) and the first 1/2 were treated with CA-C and the latter 1/2 with ACQ. As such, specimens from trees 1 and 2 were treated with CA-C, and specimens from trees 1, 3, and 4 were treated with ACQ.

For purposes of comparison, dimension lumber of both western hemlock and eastside ponderosa pine were treated at the same time (as shown in photos below).

Uptake of chemical was measured in grams, chemical retention was calculated (kg/m3), and penetration was measured in mm. "Full penetration" was considered to be 50 mm or more. Images were captured as well to show the depth of penetration. Results were particularly promising for the ACQ in that all 41 specimens had at least 50 mm penetration. The table below shows the results (averages).

| Treatment | Uptake (g) | Retention (kg/m3) | Penetration (mm) |

|---|---|---|---|

| ACQ | 879 | 1194 | 50+ |

| CA-C | 464 | 631 | 12.3 |

| Note: Specimens weighed an average of 625 g prior to treatment | |||

| Examples: Good treatment penetration | Examples: Poor treatment penetration |

|---|---|

ACQ - good penetration [western hemlock, eastside ponderosa pine, Valley pine] |

ACQ - Poor penetration [western hemlock, eastside ponderosa pine, Valley pine] |

CA-C - good penetration [eastside ponderosa pine, Valley pine, western hemlock] |

CA-C - Poor penetration [eastside ponderosa pine, Valley pine, western hemlock] |

| Photos | |

|---|---|

Logs for study after arrival at sawmil; logs represent 4 trees (marked by color) and 11 log segments (butt log, second log, etc.) |  Dick Flynn, Custom Cut Lumber in Eugene, OR sawing log from Tree 3 (butt log) |

Lumber loaded for delivery to OSU. |

|

Testing bending strength of green lumber | Testing hardness of green lumber |

Boards being loaded into the dry kiln (4/27/17) |

Danielle Korthuis, summer student intern, testing specific gravity (6/26/17) |

Katherine Leavengood, summer student intern, preparing sample boards for permeability testing (6/30/2017) |

Niko Hansen, summer student intern, preparing sample boards for treatability testing (7/12/2017) |