Under Construction (April 7th, 2024)

The Department of Wood Science & Engineering and TallWood Design Institute are equipped with a variety of equipment to assist in material characterization, prototype development, and mechanical and physical property testing. We are able to conduct a wide variety of standard test methods - see https://owic.oregonstate.edu/standard-tests for a list of some of the more common tests we conduct.

Equipment is located in several buildings on the OSU campus in Corvallis including: Richardson Hall (RH), the Oak Creek Building (OCB), and the A.A. Emmerson Advanced Wood Products Lab (EMME).

- Environmental Conditioning/Accelerated Weathering

- Drying

- Mechanical & Physical Property Testing

- Microscopy, Misc.

- Composites/Mass Timber Manufacturing

- Wood Durability/Pressure-Treating

- Wood Machining

- Pulp & Paper

Environmental Conditioning/Accelerated Weathering

- Chambers at Constant Conditions:

- Hot-dry (RH 178): 30°C/30% RH (wood EMC of 6%), 8' x 13'

- ASTM/Standards Room (RH 184): 20°C/65% RH (wood EMC of 12%), 20' x 25'

- Hot-humid (RH 180): 30°C/90% RH (wood EMC of 20%), 8' x 13'

- Cold (RH 144): 5°C, 11' x 15'

- Programmable Chambers (conditions can vary during testing) - Multi-Chamber Modular Environmental Conditioning (MCMEC; OCB) chambers:

- 3 chambers 8'x8'x8', adjustable to one chamber 8'x8'x24', or one 8'x8'x16' and one 8'x8'x8'

- Dual environment testing for panels/walls with differing conditions on either side

- Temperature Range: -30°C to +40°C

- Humidity Range: 10% to 95% RH

- UV (4 arrays, 4000W Metal Halide bulbs)

- Water spray

- Soak tank (RH 193): 4' x 4' x 8.75" deep; small heater and pump to circulate water

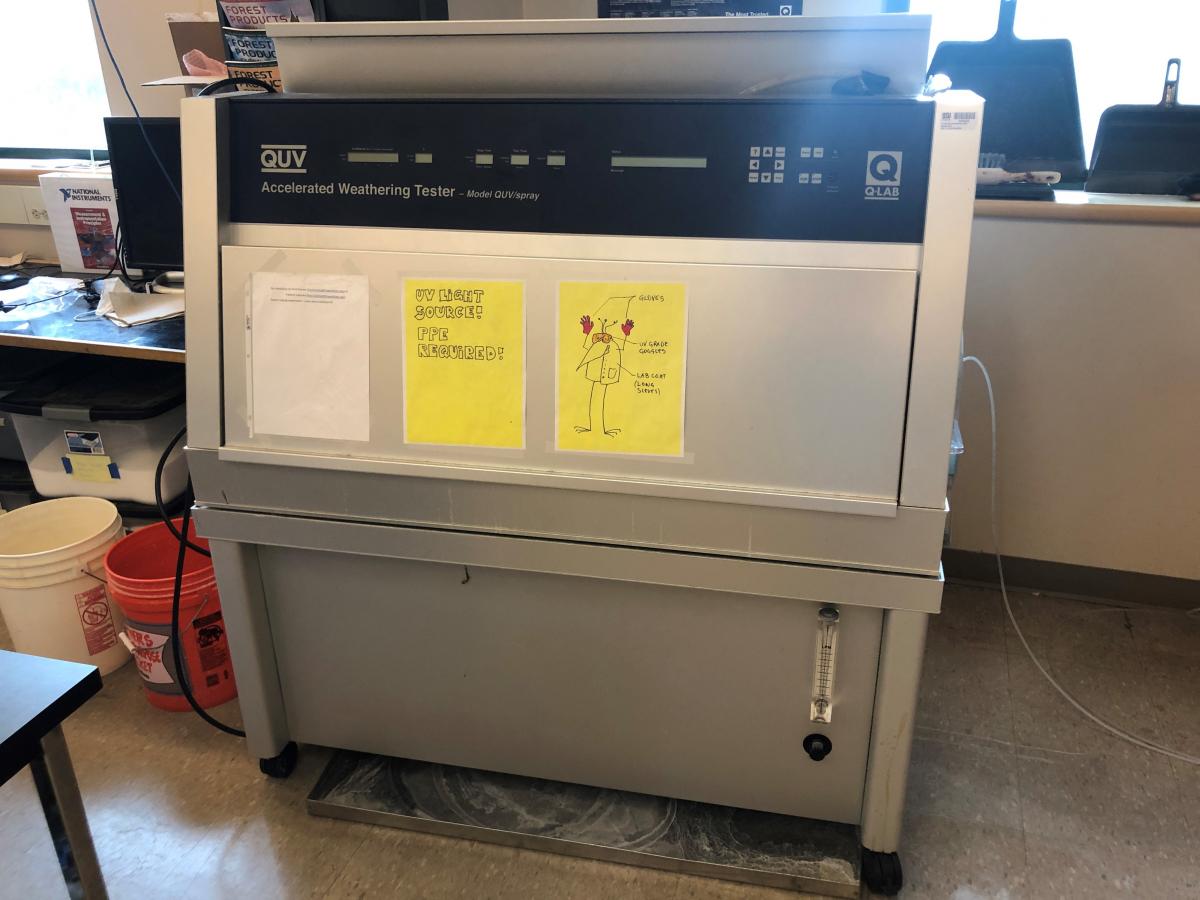

- Accelerated Weathering Tester (RH 173): Q Lab QUV/Spray, can accommodate up to 48 test specimens (19 mm thick x 75 mm wide x 150 mm long); temperature (45-80°C), water spray, UV

- Automatic Boil Tester (RH 197): for conducting ASTM D3434 (Multiple Cycle Accelerated Aging Test [Automatic Boil Test] for Exterior Wet Use Wood Adhesives)

| |

MCMEC - | QUV Accelerated Weathering Tester |

|

|

| Automatic Boil Tester | Soak tank |

- Dry kiln (RH 197): Wellons Model 8846, approx. 2 MBF - max. unit size 4'x4'x16'; maximum temperature 300°F

- Ovens (RH 174): 55°C and 103°C

- Oven (RH 193): max. temp 250°C; interior dimensions 18" wide x 13" deep

|

Dry kiln |

Mechanical & Physical Property Testing

- Universal Testing Machines:

- Instron Model 5582 (RH 170): 100 kN max capacity

- Instron Model 5988 (RH 147): 400 kN max capacity

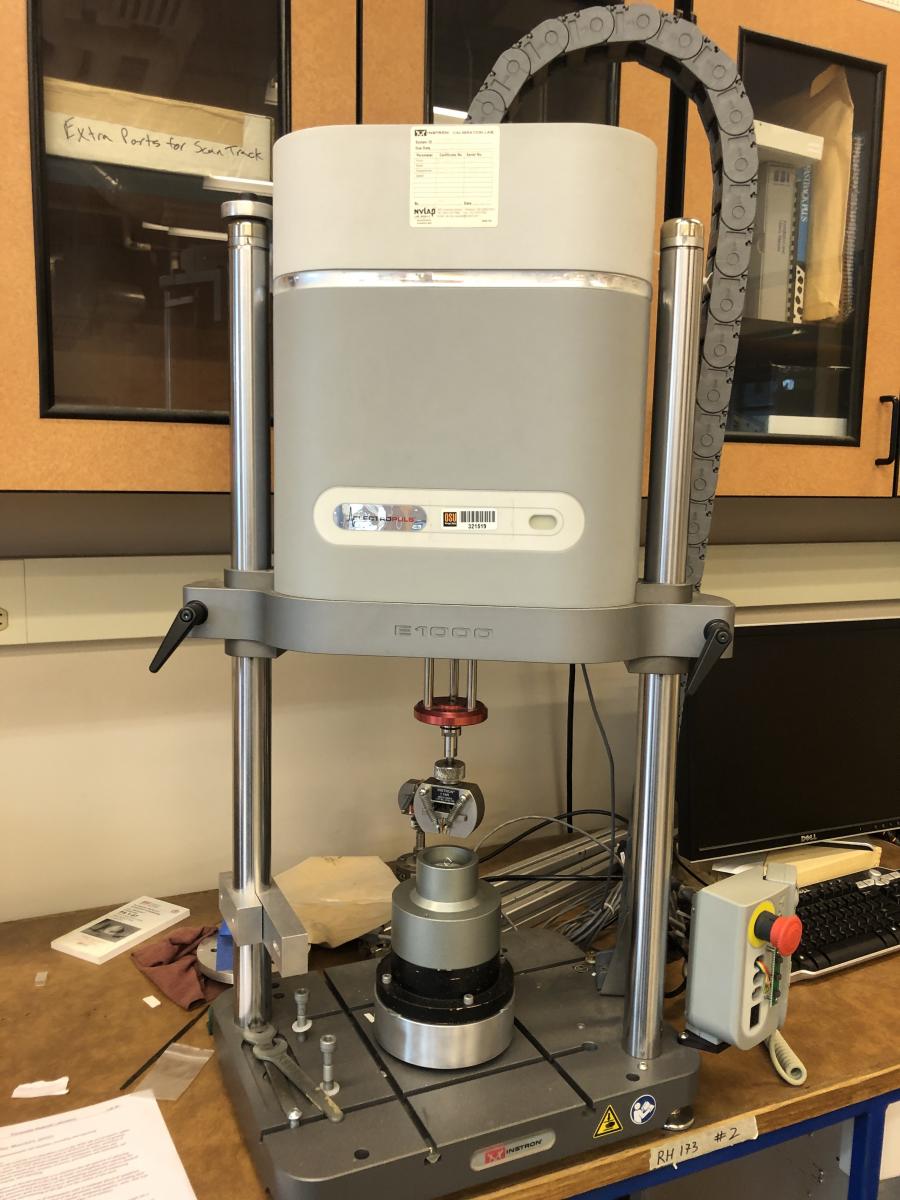

- Dynamic tester (RH 173): Instron ElectroPuls model E1000 (static capacity ±710 N; dynamic capacity ±1000 N)

- Impact tester (RH 173): Instron Dynatup Model 8200

- RH 147 equipment

- Emmerson lab equipment

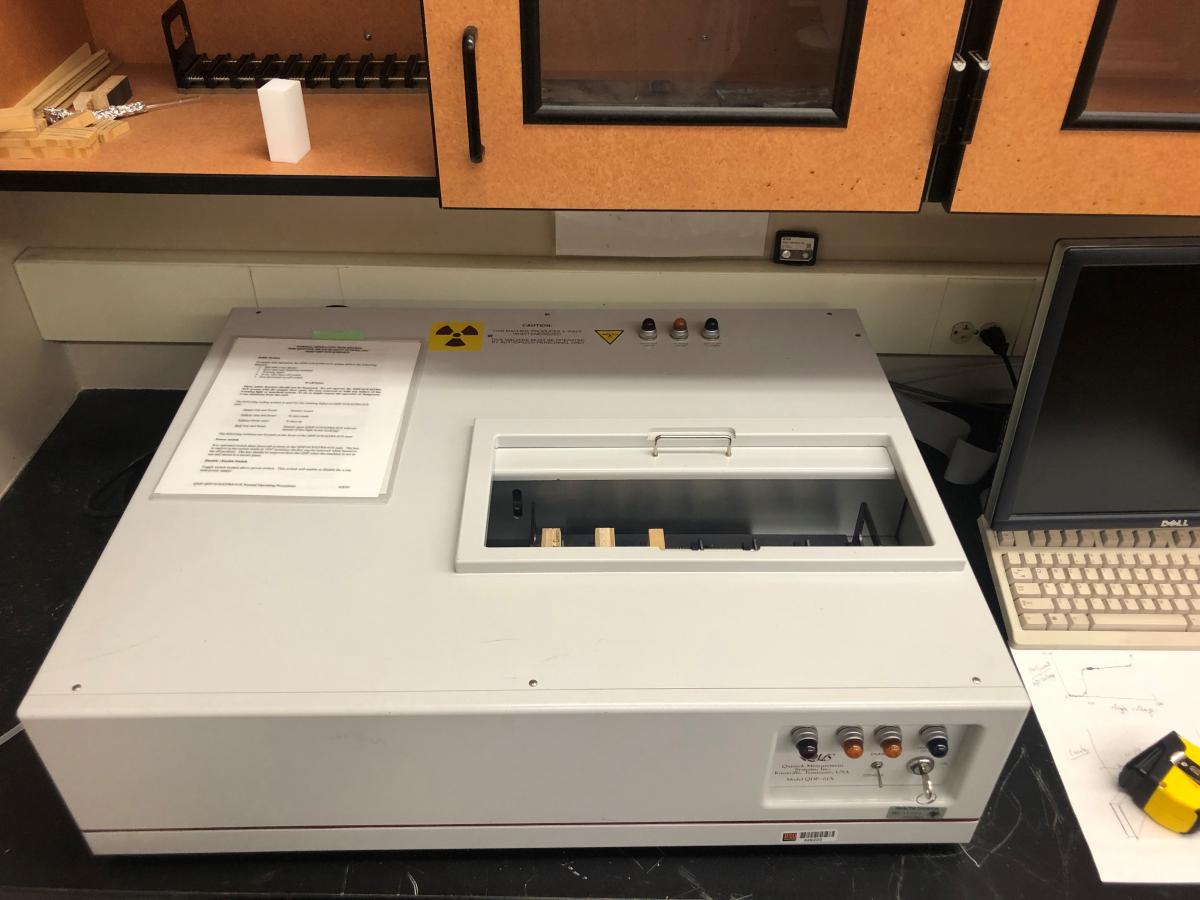

- X-ray densitometer (RH 166): Quintek Measurement Systems (QMS) QDP-01X

- Colorimeter (RH 171): Minolta Chroma Meter CR-5

- Digital Image Correlation (DIC) equipment (RH 173): Correlated Solutions, macro- and micro-scale capacity

- Computer-controlled imaging systems:

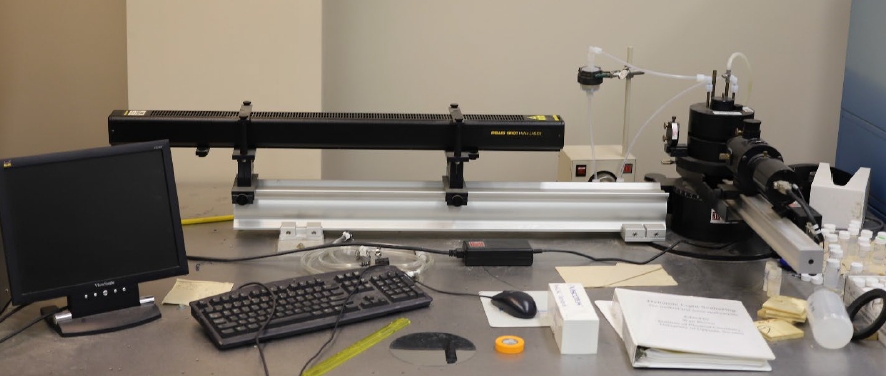

- Linear track positioning system (RH 173): Parker Daedel 204000 Series motor; Parker Compumotor SX-6 Drive; platform 3' wide by 20' long; position accuracy within 0.006 mm

- X-Y computer-controlled camera system (RH 173): can image area 6' x 6'

- X-Y laser scanning table (RH 166): Melles Griot HeNe Laser

|  |  |

| Instron UTM | Impact Tester | Dynamic tester |

|  |  |

| QMS X-ray densitometer | Colorimeter | Linear track system |

| ||

| X-Y laser scanning table | X-Y camera system |

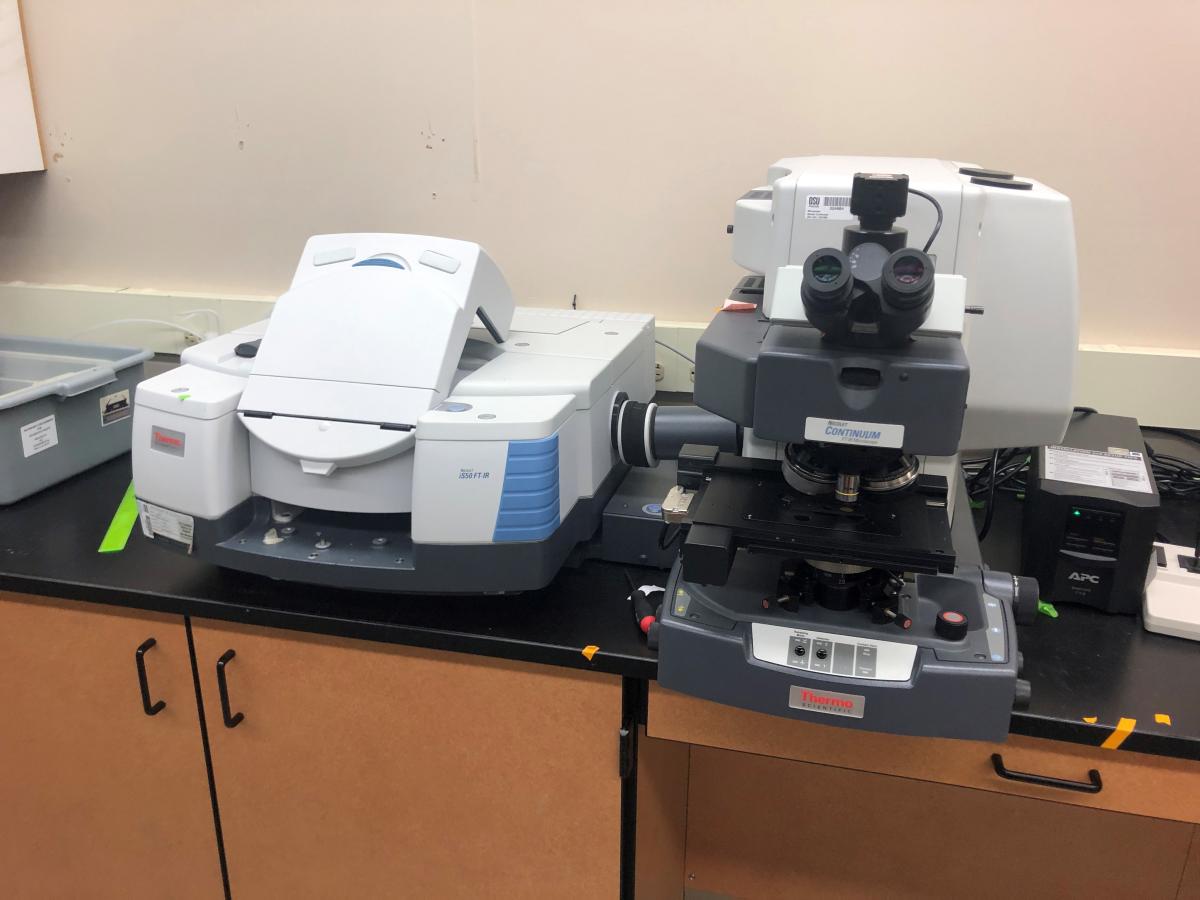

- FTIR Microscope (RH 166): Thermo Scientific iS50

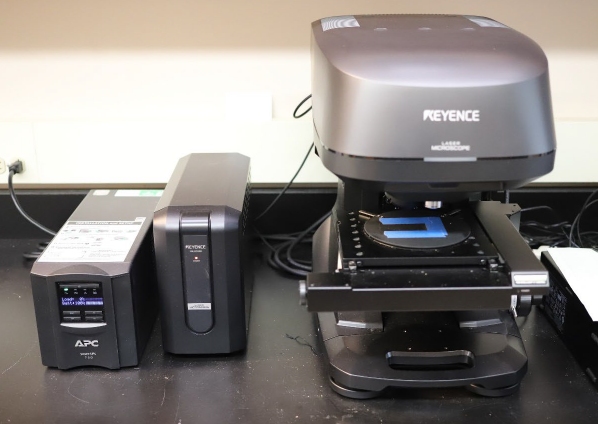

- Laser Scanning Microscope (RH 169): Keyence Model VK-X1050; 5 nm to 5 mm dual mode

- Microscopes (RH 169): Olympus stereo microscope SZX9, Olympus BH-2, Nikon Eclipse E400 fluorescence, Nikon Eclipse Ni, and others

|  | |

| FTIR microscope | Laser scanning microscope |

Composites/Mass Timber Manufacturing

- Hot presses (RH 191):

- Hydraulic press: platen dimensions 3'x3' (max temp 225°C, 800,000 lbf)

- Electric press (RH 191): Carver Auto Series Plus, platen dimensions 1'x1'

- Cold press (RH 147): Baileigh, 2'x2', 100 Ton

- Rotary drum blender (RH 191): 6' diameter

- Glue spreader/roll coater for veneer (RH 191): Quick Machinery Company, 2'

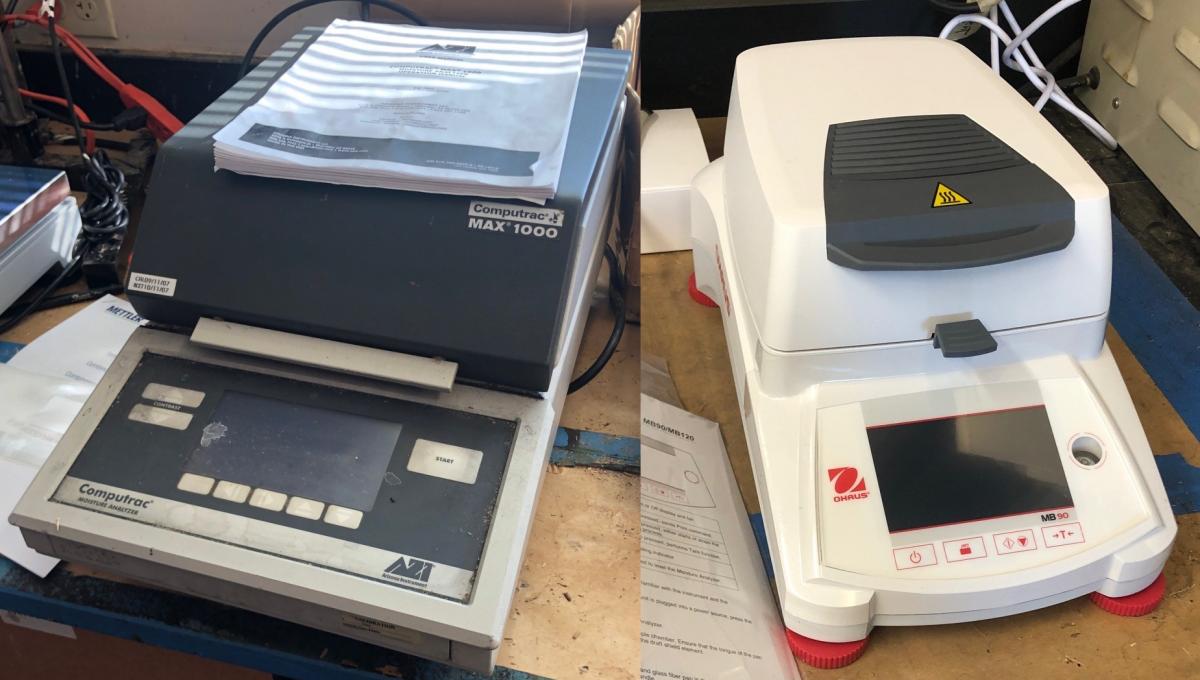

- Moisture Analyzers: Computrax MAX 1000 (OCB); Ohaus MB 90 (RH 191)

- Minda Press (EMME): Timber Press X 225, 8'x10'

- VTC press (OCB): 10"x24" platens inside sealed chamber (max temp 180°C saturated steam, 600,000 lbf)

|  |

| 2' veneer glue spreader | 3'x3' hot press |

|  |

| 1'x1' hot press | 2'x2' Cold press |

|  |

| Rotary drum blender | Moisture analyzers |

|  |

| VTC press | Press for mass timber Virtual tour of Emmerson Lab |

Wood Durability/Pressure-Treating

- Pressure cylinder (RH 197B): 17" diameter, 47" deep

- Small cylinder (RH 197B): 8.25" diameter, 32" deep

- Vacuum pressure soak tank (new)

- Second floor lab... (soil block testing)

|  | ||

| 17"x47" treating cylinder | 8"x32" treating cylinder |

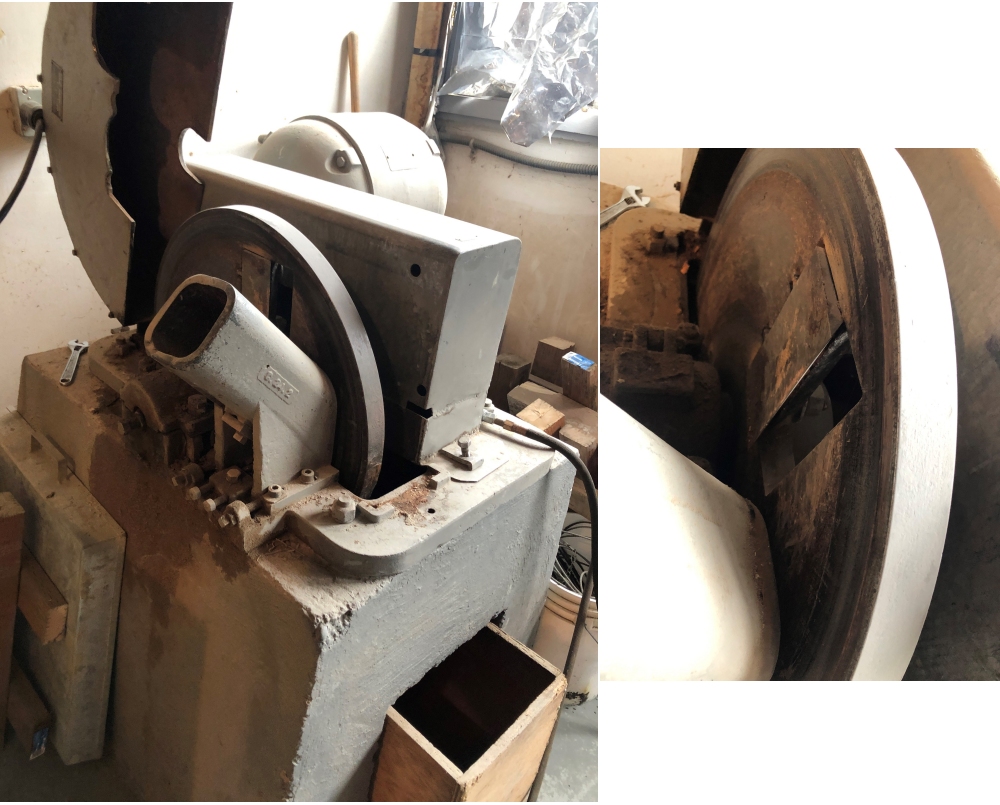

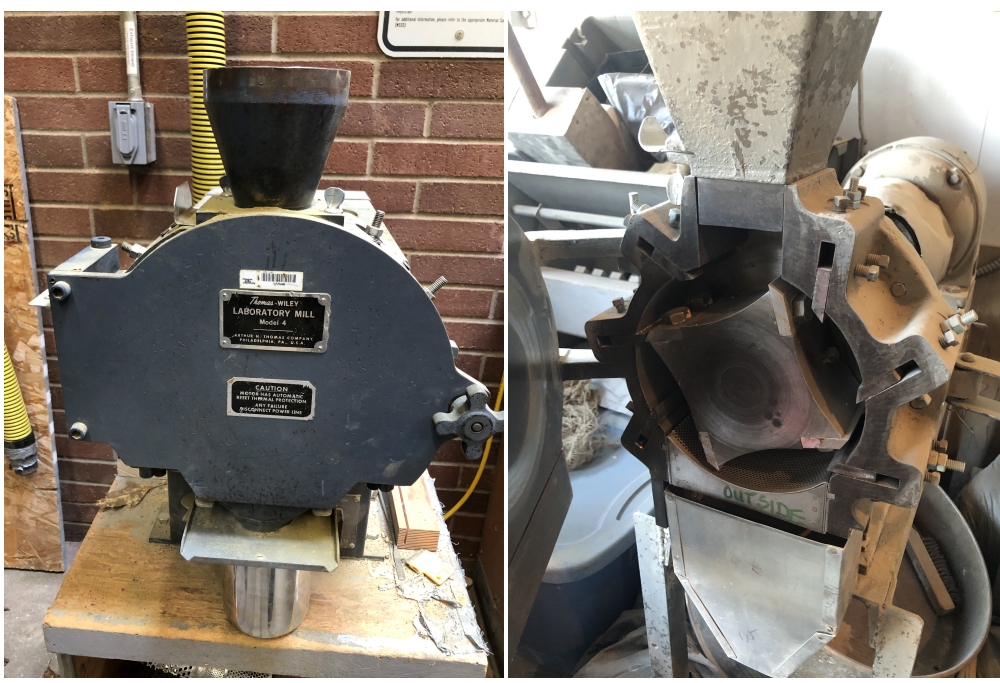

- Chippers/grinders/hammermill (OCB): Appleton Machine Company chipper (24"); hammermill; Wylie Mill Model 1 (OCB); Wylie Mill Model 4 (RH 197)

- Drum Sander (RH 197): Grizzly G0450 (37")

- Bandsaw (RH 197): Grizzly 0640X (17")

- Table saw (RH 197): Sawstop

- 5-axis CNC (EMME) - Biesse Uniteam UT-9; can machine panels up to 10' wide by 29' long

- Kuka Robot (EMME): model KRC4 KR120 R2700 Extra_HA\Floor

- Planer (EMME): Leadermac LMC 460 Planermac

- Table saw (EMME): Martin T65

- Chop saw (EMME): Cantek PCS24, 24"

- Veneer slicer (OCB): 29" wide x 5" high

- Oak Creek Wood Shop (OCB)

- Planer: Powermatic 201HH (22")

- Bandsaws: Laguna LT 24 (24"); Laguna LT14BX220-250 (14")

- Jointer: Powermatic 1285-3 (12")

- Sanders: Jet oscillating drum sander (22-44 OSC); Jet oscillating spindle sander (JOVS-10); Jet belt sander (6"x89")

- Router table: Kreg model

- Lathes: Jet JWL-1015VS, 10"x15" Variable Speed (Qty. 5)

- Drill press: Powermatic 2800B (18")

- Table saw: Sawstop

- Planer: Powermatic 201HH (22")

- Wood turning studio (OCB)

- Lathes: Jet JWL-1221VS 12"x21" Variable Speed; Nova Galaxi dvr; Vega 2600 bowl lathe; Laguna Revo 24|36

- Bandsaw: Laguna LT14BX220-250 (14")

- Digital fabrication lab (OCB)

- Small CNCs: Pocket NC, ShopBot Desktop Max D3624 (36"x24")

- 3D printers: MakerBot Replicator+; Delta Wasp 20x40

- Laser engraver: Epilog Zing 16

|  |

| 3' drum sander | Kuka robot |

| | |

| Planer & jointer | Nova Galaxi dvr lathe |

| |

| 24" bandsaw | veneer slicer (knife in inset image, lower right) |

|  |

| hammermill (input/output images) | chipper (input/output images) |

|  |

Wiley Mill 4 (left, closed); Wiley Mill 1 (right, open) | Martin T65 table saw |

|  |

| Cantek chop saw | Biesse CNC |

- Canadian Standard Freeness Tester (RH 168)

- British Sheet Mold (RH 168)

|

| Pulp & paper lab |

Wood Physics/Moisture Relations Laboratory (RH 185)